Optimizing Workflow Efficiency with Advanced AGV and AMR Solutions

Industries reliant on material handling and automation faced challenges like workflow inefficiencies, human limitations, and safety concerns.

As traditional methods fell short in meeting the requirements of today’s high-paced industrial environments, the demand for faster, safer, and more efficient systems grew. Innovations in AGV/AMR respond to these demands among various industries.

What is AGV (Automated Guided Vehicle)?

An AGV is a mobile robot that follows predefined routes using guidance technologies such as magnetic strips, wires, or markers embedded in the floor. They are typically used in structured environments where predictability and control are prioritized.

What is AMR (Autonomous Mobile Robot)?

AMR can navigate dynamically as a more advanced AGV using sensors, cameras, LiDAR, and AI algorithms. Hence, it is not confined to fixed routes and adjusts in real-time based on environmental changes, obstacles, or tasks.

Contributions of AGV and AMR Systems

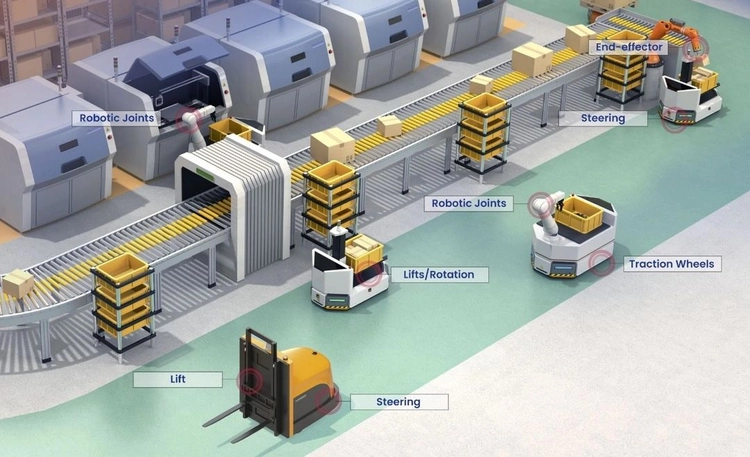

Motors such as stepper, hybrid stepper, BLDC, Servos, frameless, slotless, linear actuators, and many more form the backbone of AGV and AMR systems, enabling their mobility,

precision, and adaptability in diverse applications.

• Mobility and Load Handling: Motors like BLDC and servo power drive wheels enable smooth movement, rapid acceleration, and precise stopping despite heavy loads.

• Navigation and Steering: High-precision stepper or servo motors allow accurate directional control for tight turns and obstructed paths.

• Modularity: Frameless and slotless motors are ideal for tight spaces with their compact designs.

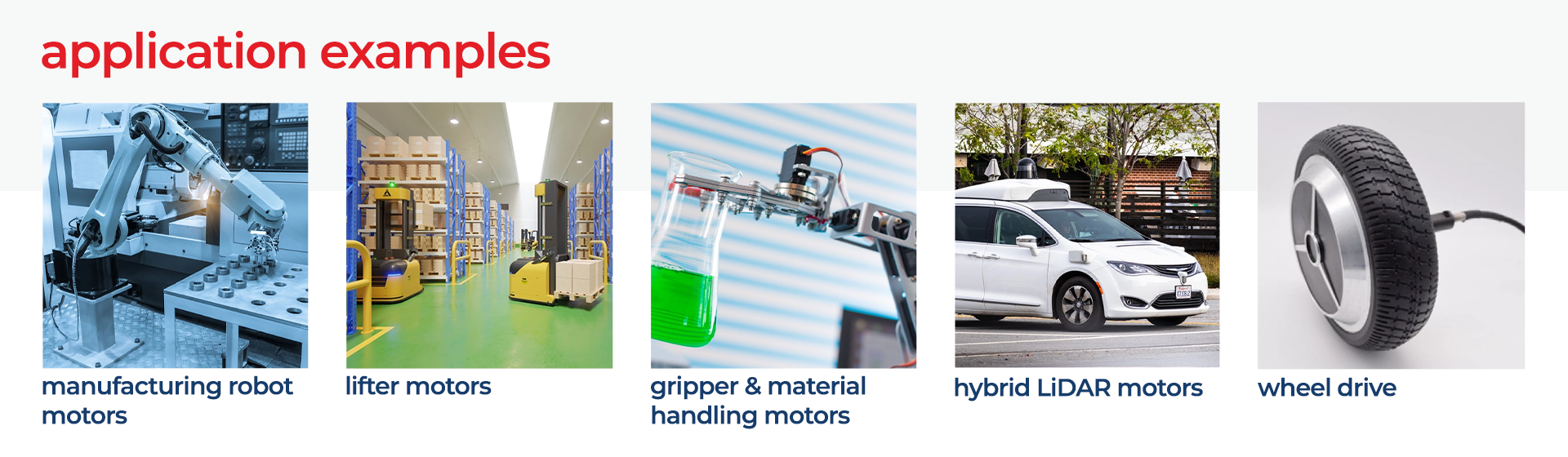

As a one-stop shop for motion control solutions, Lin Engineering develops and manufactures high-quality DC motors capable of withstanding

extreme environments with various custom and optimized motor solutions to fit your specific applications.

Their extensive portfolio includes stepper, BLDC, servo, frameless, slotless, and many more tailored to your needs.

They offer prototyping and scalable production from a few units to 10 million; ensuring ongoing product support, and timely delivery, within budget.

ISO9001 and AS9100 compliance ensures reliability, while U.S.-based support provides responsive service and cost-effective solutions.

Now represented by SACA Europe, Lin Engineering continues to expand its reach, delivering customized, seamless, and high-performance motion solutions that enhance AGV and AMR efficiency and dependability.

For Lin Engineering product catalog: